A huge portion of Ocean Mist Farms’ Northern California growing region resides in the fertile fields of Castroville – The Artichoke Center of the World – and nestled in the rich Salinas Valley. Here we grow our artichokes virtually year-round, the majority of which are from patented proprietary varieties. In the winter months, much of our artichoke growing operations transition to Oxnard and the Coachella Valley, in Southern California, Yuma, Arizona and Baja, Mexico.

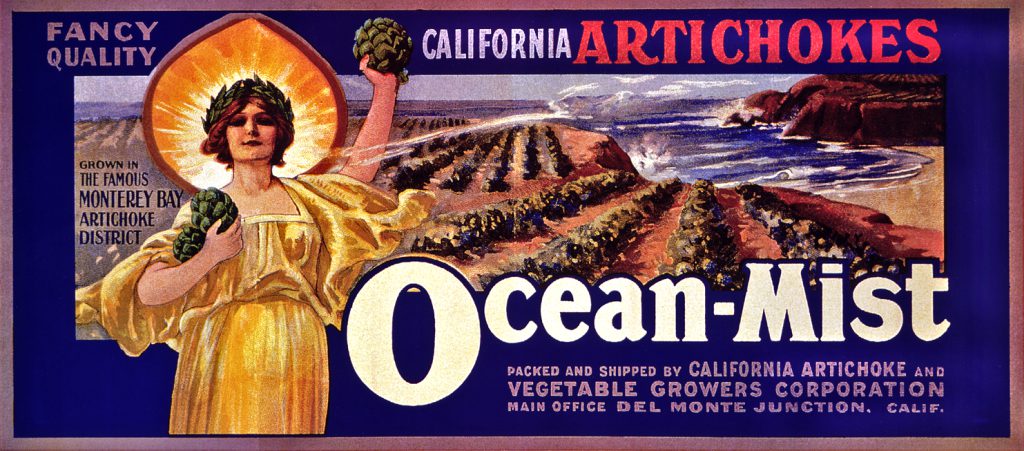

This perennial plant grows best in cooler climates and thrives in temperate weather environments – especially coastal areas – with a low risk of frost. Artichokes love a Mediterranean climate, which we are fortunate to have here in the Monterey Bay area.

Not technically a vegetable, if left to fully mature artichokes will bloom into beautiful rustic flowers that are a gift from Mother Nature to behold. Greek mythology suggests the artichoke was created by Zeus. It is believed to be one of the oldest foods known to humans.

At Ocean Mist Farms we start our artichoke plants in a greenhouse for about 30-40 days before planting those “starters” or seedlings in the fields. Within approximately three months, the center artichoke with the thickest stalk will mature into the “Primary,” which is the largest artichoke on the plant.

Artichoke plants produce artichokes – or “buds” – in phases. The primary will be harvested first, and then the secondary, tertiary, and baby artichokes will be harvested in several subsequent sweeps of the field based on their size and what the crews are packing for on a given day. There’s quite a strategy to what is harvested on any given day. It’s a continual exercise to know the current state of supply and demand, and compare that with what artichoke sizes are mature and ready for harvest in each field.

The average number of artichokes each plant will produce can vary by variety, but typically will yield approximately 8-10 buds per plant. This means there will be several harvests from each plant before it has fully produced all its offering.

Artichokes are hand-cut and collected, and to suggest this is hard, hot, grueling work is a gross understatement. They are one of the most challenging and labor-intensive vegetables to harvest. Working from the cold foggy mornings through the hot sunny afternoons, field crews enter the furrows of the fields with a back-pack style “canasta” on their back to transport the freshly cut artichokes in.

A full canasta can weigh 80-100lbs before the field worker returns to the mobile harvester where they will dump their entire cache onto the machine’s intake conveyer belt, or stack their full canasta at the intake area and grab an empty one before heading back out to the field to do it all over again. They can complete up to 35 passes in one day’s harvest, walking up to five miles per day. Much, much respect for the work these field crews do every day.

The conveyor belt moves the artichokes directly up into the packing machine where a fast-working and perfectly synchronized crew is simultaneously inspecting, sorting, sizing and packing the artichokes into a variety of pack styles, which are then packed into the correct cartons. Everyone has a very specific job to do and they each perform their role with an impressive rhythm with their teammates to work as efficiently as possible.

The packed boxes and cartons are moved down the line to the stacking area where each box is labeled with a sticker detailing the date, time, and field of harvest. This info is especially important in the event any item needs to be traced back to its growing region and field of origin.

The labeled boxes are then stacked onto cooler-bound trucks in, this, the final step of the field harvest. The freshly harvested, packaged, packed, and stacked boxes will go from the fields to one of our coolers in less than four hours.

The pallets of artichokes will be precooled upon arriving at the cooler, after which they are moved into state-of-the-art cold rooms which are kept at 34⁰ to ensure optimum freshness. All products will remain in refrigeration until loaded onto (34⁰ refrigerated) trucks to begin their journey to retailers and foodservice operators nationwide and all over North America.

The next time you enjoy some Gold Standard Ocean Mist Farms artichokes – whether prepared at home or in a restaurant – think of all the hard work and effort that went into producing these amazing delicacies.

Before We lived in N. Nevada for years then Florida & back to Nevada Moved ~ we lived in the San Francisco Bay area and went to Castroville frequent. We still miss the annual Artichoke festival very much!! Great product that we’ve been eating all our lives. Thank You for your excellent chokes!!

I have been to Castroville and seen the fields of you wonderful artichokes and enjoy them every week of the year and put them on our customers menus.

This story was amazing. I love to make artichokes for my daughter, granddaughter and me the way my Italian mom used to make them. We love Ocean Mist Artichokes. Thank you.

Several years ago my wife and I attended the artichoke festival in castroville and actually went out to the fields to see how they’re grown this was truly an amazing sight to see

I will eat no other brand. When my local Kroger quit carrying them and started selling Dole, I tried them twice and there is no comparison to Ocean Mist, so I quit buying them at Kroger.

I love artichokes! After you plant them in the field, how long does it take for them to bare chokes that a person can eat? Please advise. Thank you, Linda

Absolutely educational. I had no idea about the plant itself or the harvesting. Thank you for sharing. Love your brand and you have a loyal buyer for life!

I enjoyed learning how much work goes into harvesting artichokes. They are one of my favorite foods. Thank you to all your workers, you do a wonderful job.

I have enjoyed artichokes since I was a little girl. My mother would stuff them with her own Italian bread crumbs. I buy them whenever I can find them in the grocery store. There are so many ways they can be prepared. I often have them as my main dish. Beautiful story, makes me appreciate them even more.

Great product, interesting to see the process.. Thanks

What a fantastic read! Many folks don’t think about where the food they are eating has come from, and all of the work that takes place, to get that food from field (or farm) to table. The pictures and video are beautiful. My many thanks to all of the workers and their hard and detailed labor to bring us the freshest and best tasting artichokes possible!

My husband and I love artichokes. What an eye-opener to see the growth and delivery process Ocean Mist has accomplished. We definitely appreciate all the hard work. Keep it up!!